- Linear programming

Solving assignment problem with lpSolve in R

- Linnart Felkl

The assignment problem is a classic problem in linear program . If, for example, you have n jobs that need to be manufactured during the upcoming shift (in a manufacturing plant) and you have m machines to produce these tasks, then you want to assign the jobs to machines in an optimal way. In this say you might want to reduce the manufacturing costs incurred, hence you want to find the cost optimal production plan. The constraint, in this example, is that each machine can only fulfill one job during the upcoming shift. All jobs needs to be scheduled, i.e. assigned to a machine.

The problem can be stated in a mathematical model. Below the problem is stated for a case where there are 3 jobs and 3 machines. The cost of producing job 1 on machine 1 USD but 2 USD when producing it on machine 2. Job 2 costs 2 USD on machine 1 and 3 USD on machine 2. Job 3 costs 5 USD on machine 1 and 1 USD on machine 2. Machine 3 can perform job 1 for 2 USD and jobs 2 and 3 for 3 USD respectively.

The mathematical model for this looks as follows:

We can model and solve this problem with the lpSolve package in R, a package for linear programming (for continous and integer problems). The lp.assign function can do the job:

lp.assign is a function specifically meant for solving the assignment problem. The assignment problem by definition is a problem where all decision variables are integer variables. We therefore do not need to specifically tell lp.assign that the decision variables must be considered as integer variables.

Let us see the minimal costs that we must face during the upcoming shift:

Let us see the cost minimal production plan for the upcoming shift:

The transportation problem is another classical problem. You can see me solving it in R – here: Solving Bronson’s transport problem with lpSolve , using lp.transport .

Data scientist focusing on simulation, optimization and modeling in R, SQL, VBA and Python

You May Also Like

How used machinery powers smart factories

Used CNC machines in supply chain strategies

Scheduling a CNC job shop machine park

Leave a reply.

- Default Comments

- Facebook Comments

Leave a Reply Cancel reply

Your email address will not be published. Required fields are marked *

This site uses Akismet to reduce spam. Learn how your comment data is processed .

- Entries feed

- Comments feed

- WordPress.org

Privacy Overview

Assignment Problem: Meaning, Methods and Variations | Operations Research

After reading this article you will learn about:- 1. Meaning of Assignment Problem 2. Definition of Assignment Problem 3. Mathematical Formulation 4. Hungarian Method 5. Variations.

Meaning of Assignment Problem:

An assignment problem is a particular case of transportation problem where the objective is to assign a number of resources to an equal number of activities so as to minimise total cost or maximize total profit of allocation.

The problem of assignment arises because available resources such as men, machines etc. have varying degrees of efficiency for performing different activities, therefore, cost, profit or loss of performing the different activities is different.

Thus, the problem is “How should the assignments be made so as to optimize the given objective”. Some of the problem where the assignment technique may be useful are assignment of workers to machines, salesman to different sales areas.

Definition of Assignment Problem:

ADVERTISEMENTS:

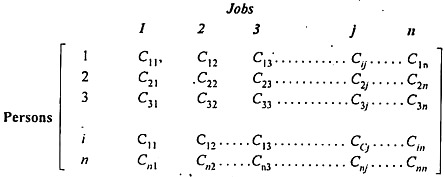

Suppose there are n jobs to be performed and n persons are available for doing these jobs. Assume that each person can do each job at a term, though with varying degree of efficiency, let c ij be the cost if the i-th person is assigned to the j-th job. The problem is to find an assignment (which job should be assigned to which person one on-one basis) So that the total cost of performing all jobs is minimum, problem of this kind are known as assignment problem.

The assignment problem can be stated in the form of n x n cost matrix C real members as given in the following table:

Download Free PDF

Nonlinear Assignment Problems in Manufacturing

Nonlinear Assignment Problems (NAPs) are combinatorial optimization problems for which no exact algorithm exists that can solve them in reasonable computational time. They enjoy applications in diverse areas, such as location theory, data association problems, physics, manufacturing and many others. This talk is divided into two parts. First an overview of NAPs will be presented, where di erent formulations, exact and heuristic solution methods, and other characteristics of NAPs will be discussed.

Workers assignment problems in manufacturing systems: A literature analysis

Ieee account.

- Change Username/Password

- Update Address

Purchase Details

- Payment Options

- Order History

- View Purchased Documents

Profile Information

- Communications Preferences

- Profession and Education

- Technical Interests

- US & Canada: +1 800 678 4333

- Worldwide: +1 732 981 0060

- Contact & Support

- About IEEE Xplore

- Accessibility

- Terms of Use

- Nondiscrimination Policy

- Privacy & Opting Out of Cookies

A not-for-profit organization, IEEE is the world's largest technical professional organization dedicated to advancing technology for the benefit of humanity. © Copyright 2024 IEEE - All rights reserved. Use of this web site signifies your agreement to the terms and conditions.

IMAGES

COMMENTS

Nov 21, 2019 · The assignment problem is a classic problem in linear program. If, for example, you have n jobs that need to be manufactured during the upcoming shift (in a manufacturing plant) and you have m machines to produce these tasks, then you want to assign the jobs to machines in an optimal way. In this say you might want to reduce the manufacturing ...

After reading this article you will learn about:- 1. Meaning of Assignment Problem 2. Definition of Assignment Problem 3. Mathematical Formulation 4. Hungarian Method 5. Variations. Meaning of Assignment Problem: An assignment problem is a particular case of transportation problem where the objective is to assign a number of resources to an equal number of activities so as to minimise total ...

Module 4: Transportation Problem and Assignment problem Prasad A Y, Dept of CSE, ACSCE, B’lore-74 Page 3 Since the supply from row O1 is completed cancel the row O1. The demand for column D2 remain 350 – 50 = 50. From the remaining table the north-west corner cell is (O2, D2). The minimum among the supply

Oct 18, 2013 · Workers assignment problems (WAPs) are found in several types of manufacturing systems. Typically, WAPs are known to greatly impact the system performance. Numerous research works related to WAPs ...

The Assignment Problem: An Example A company has 4 machines available for assignment to 4 tasks. Any machine can be assigned to any task, and each task requires processing by one machine. The time required to set up each machine for the processing of each task is given in the table below. TIME (Hours) Task 1 Task 2 Task 3 Task 4 Machine 1 13 4 7 6

The case study involves a layout problem that can be represented as a Quadratic Assignment Problem (QAP). Due to the nature of the manufacturing process, certain machinery need to be allocated in close proximity to each other. This issue is incorporated into the objective function through assigning high penalty costs to the unfavorable allocations.

problem. There are two main methodologies used in this research. First, assignment problem is employed and capacitated vehicle routing problem with time window (VRPTW) is used later. The assignment problem clusters 377 branches into 3 groups each group belongs to each DC and VRPTW produces routes for each DC daily.

a comprehensive quadratic assignment problem is developed for the assignment of machines of each part manufacturing cell, sub-assembly tasks of each sub-assembly cell as well as the assignment of different cells and final assembly tasks within the shop floor in their relevant predetermined locations.

Workers assignment problems (WAPs) are found in several types of manufacturing systems. Typically, WAPs are known to greatly impact the system performance. Numerous research works related to WAPs have been published. In this work, we analyze this literature according to several types of criteria. We first take into account such important features of the WAP as workers flexibility, the number ...

Jul 1, 2024 · In this research, a variation of the assignment problem is formulated. Diverging from many studies which model the assignment problem in a deterministic setting, we consider a noisy and complex manufacturing process consisting of several workstations, each of which must be assigned a machine from a set of machine types which vary randomly according to processing time. The objective is to ...